#Batch Coding Conveyor

Explore tagged Tumblr posts

Text

How to Safely Load and Unload Cement from Silos: A Guide for Site Operators

Cement silos are essential storage units used on construction sites to store bulk cement and fly ash efficiently. Ensuring safety during the loading and unloading process is vital for maintaining worksite productivity, preventing accidents, and preserving material quality. This guide provides site operators with practical knowledge on handling cement silos while following the latest safety standards used by industry leaders in road construction and material handling equipment.

What is a Cement Silo?

A cement silo is a specialized container used for storing dry bulk materials like cement and fly ash. These silos come in various types, including vertical silos, horizontal silos, and mobile silos. They are commonly used in infrastructure projects, ready-mix concrete plants, and road construction sites. Silo manufacturing companies in India design these units to handle large volumes efficiently and safely, often aligning with IS code standards and CPCB dust control norms. Operators should confirm whether the silo complies with IS 4925:2004 to ensure safe batching practices.

Why Proper Handling of Cement Silos is Crucial?

Proper handling of cement silos is essential to avoid material spillage, equipment damage, and safety risks. Incorrect procedures can lead to clogged discharge systems, dust pollution, and even structural damage to the silo. Following safe loading and unloading methods ensures that operations run smoothly and reduces downtime, especially when working with fly ash silo systems. Some advanced silos are designed with user-friendly safety features like digital level indicators and automatic venting systems that minimize human error.

Cement Loading Process: Step-by-Step Guide

The loading process involves transferring bulk cement into the silo from a tanker or bulk carrier. Here's how to do it safely:

Check all connections and pressure levels before starting.

Use appropriate conveyors or blowers as recommended by the equipment manufacturer.

Monitor the silo’s level indicator to avoid overfilling.

Ensure the dust collector is operational to prevent airborne particles. Skipping these steps can lead to material loss and air contamination.

Pro Tip: In one project involving high-output cement batching, an operator avoided a costly system shutdown by double-checking the pressure settings against the values in the manufacturer’s manual before initiating loading. Always confirm tanker pressure settings to prevent structural stress on the silo.

Cement Unloading Process: Best Practices

Unloading cement from silos should be done systematically:

Open discharge valves slowly to control material flow.

Use gravity or pneumatic systems as per equipment specifications.

Maintain silo pressure balance by using a functional air vent.

Clean the discharge line regularly to avoid clogging. Leading manufacturers often recommend scheduled maintenance and some provide digital alerts on silo health via SCADA systems, especially on high-volume projects.

Safety Measures to Follow During Loading and Unloading

Safety should always come first during cement handling. Key measures include:

Wearing personal protective equipment (PPE) such as helmets, goggles, and dust masks.

Implementing lockout/tagout systems to prevent accidental starts.

Installing emergency stop buttons near the control panel.

Using dust suppression equipment to reduce inhalation risks. Many construction equipment suppliers now integrate dust filters and pressure relief systems that comply with national safety standards.

Real-World Note: During a recent highway expansion project, one site team reduced handling-related delays by 30% by conducting pre-shift safety inspections and using silo systems with automatic dust control features.

Maintenance Tips for Cement Silos

Routine maintenance extends the life of a cement silo and enhances safety:

Inspect structural components for cracks or corrosion.

Clean filters and pressure relief valves.

Lubricate moving parts such as screw conveyors.

Keep a logbook of inspections and repairs. Several Indian silo manufacturers now provide maintenance kits and digital maintenance reminders for efficient site management.

How Modern Cement Silos Improve Safety and Efficiency

Advanced cement silos come equipped with automation and smart features:

Digital level indicators reduce manual checks.

PLC and SCADA systems allow real-time monitoring.

Better insulation and ventilation improve material preservation.

Adopting modern silo technology improves project timelines and supports remote monitoring features particularly useful in large-scale highway and infrastructure projects.

To Conclude

Handling cement silos properly is a key part of safe and efficient construction site operations. Following best practices for loading, unloading, and maintenance helps prevent accidents and material wastage. By choosing reliable equipment and adhering to safety protocols, site operators can ensure a smooth and secure workflow across construction and infrastructure projects.

FAQs

1. What is the purpose of a fly ash silo in construction?Ans: Fly ash silos store fly ash, a byproduct of coal combustion used in cement and concrete mixes to improve strength and durability. These silos help keep the material dry and uncontaminated. For projects in humid areas, look for silos with moisture control systems.

2. How often should cement silos be inspected?Ans: At a minimum, silos should be inspected once a month. For high-use sites, bi-weekly checks are recommended. Focus on structural integrity, discharge lines, and dust filtration systems. Sites that use SCADA-enabled systems can automate this process with real-time alerts.

3. Can one cement silo be used for different materials?Ans: Technically yes, but not advisable. Using the same silo for both cement and fly ash can lead to contamination and inconsistent mixing quality. Best practice is to use dedicated silos for each material.

4. What are the common causes of blockages in cement silos?Ans: Moisture infiltration, lack of routine discharge cleaning, and irregular maintenance schedules are major causes. Using anti-bridging devices, air dryer systems, and regular vent cleaning helps prevent buildup.

5. Are mobile silos a better option for remote projects?Ans: Yes. Mobile silos are particularly useful for projects in remote or temporary locations. They offer quick setup and disassembly, and reduce transportation costs by eliminating the need to haul cement daily from fixed storage units.

0 notes

Text

4 Must-Have Candy Manufacturing Machines for Efficient Production

If you're a confectioner aiming to scale up candy production or boost efficiency, the right equipment makes all the difference. Whether you're crafting caramels, gummies, hard candies, or chocolate-coated treats, reliable candy manufacturing equipment helps you maintain consistency, reduce waste, and meet demand without compromising quality.

In this guide, we break down the top four machines every candy business needs to streamline operations and produce top-tier confections.

1. Candy Cooker (Batch or Continuous)

No matter your recipe, cooking sugar mixtures to precise temperatures is the foundation of every successful candy. From glucose syrups to fruit purées, proper heat control ensures flavor, texture, and color remain consistent across batches.

Why it matters:Undercooked candy can be sticky or unstable. Overcooked batches may crystalize or burn. The right candy cooker ensures repeatable results every time.

What to look for:

Accurate digital temperature controls

Vacuum cooking options for moisture control (ideal for gummies and soft candies)

Food-grade stainless steel construction

Choose batch cookers for flexibility and small batches, or continuous cookers for high-volume production

Pro Tip: If you manufacture both hard and soft confections, consider a dual-purpose cooker or modular setup.

2. Candy Depositor or Moulding Machine

The candy depositor is where your mixture takes shape — literally. Whether you're filling molds for gummies or forming chewy pieces, this machine ensures portion control and consistent product sizing.

Why it matters: Uniform size and weight ensure better packaging, setting, and quality control — and help keep your ingredient costs predictable.

What to look for:

Interchangeable mold and nozzle designs

Programmable portion sizes

Heated hoppers (prevents premature crystallization)

Compatibility with various consistencies — from viscous syrups to liquid centers

From tabletop depositors for small-batch candy makers to fully automated moulding systems, there’s a solution for every scale.

3. Cooling Tunnel or Cooling Cabinet

Once formed or coated, your candy must cool under controlled conditions. A cooling tunnel or cooling cabinet stabilizes the product, locking in texture and finish.

Why it matters: Improper cooling can cause chocolate bloom, sticky gummies, or deformed shapes. Temperature and humidity control are crucial at this stage.

What to look for:

Adjustable temperature and airflow settings

Multi-tier or conveyor-style layouts for high output

Easy-to-clean design to meet hygiene standards

Humidity control to prevent condensation and spoilage

Cooling is not just a post-production step — it’s a key quality control point in your candy line.

4. Candy Packaging Machine

Great candy deserves great presentation — and protection. Whether you sell retail-ready treats or bulk packs, the right candy wrapping machine or packaging system helps preserve freshness and appeal.

Why it matters: Modern packaging protects against moisture, oxygen, and tampering. It also improves shelf life and retail acceptance.

What to look for:

Packaging formats: flow wrap, pillow pack, twist wrap, jars, sachets

Throughput speed that fits your production needs

Integration with batch coding or expiry date printing

Compact design with food-grade materials

Startups may benefit from semi-automatic packaging machines that allow manual feeding with automated sealing, balancing cost and efficiency.

Final Thoughts: Start Smart with the Right Candy Equipment

These four essential machines — cooker, depositor, cooling system, and packaging unit — form the backbone of any successful candy production line. Whether you're starting small or scaling up, focus on candy production equipment that is:

Scaled to your current output

Built for future expansion

Easy to clean, operate, and maintain

Certified for food safety and hygiene standards

Need Help Choosing Equipment?

At Latini Hohberger Dhimantec, we specialize in high-performance candy and chocolate manufacturing machinery. Our equipment is used by both artisanal producers and global brands — offering modular, durable, and precision-engineered solutions built to grow with your business.

🔗 Explore Candy Equipment at LatiniUSA.com

Source URL: Blogspot.com

0 notes

Text

Bottle Labeling Machine: Complete Guide to Precision Product Labeling

What is a Bottle Labeling Machine?

A bottle labeling machine is an automated or semi-automated system used to apply labels onto bottles of various shapes and sizes—round, flat, oval, or square. These machines are engineered for high accuracy, speed, and uniformity, significantly reducing labor costs and errors associated with manual labeling.

Whether it's a wrap-around label on a soda bottle or a front-and-back label on a shampoo container, these machines handle it all with seamless efficiency.

Types of Bottle Labeling Machines

1. Manual Bottle Labeling Machines

Ideal for small-scale or home-based operations

Hand-cranked or foot-pedal operated

Low investment, minimal automation

2. Semi-Automatic Bottle Labeling Machines

Operator places the bottle, and the machine handles the labeling

Perfect for startups and small to mid-sized businesses

Compatible with wrap-around, single-side, and double-side labels

3. Fully Automatic Bottle Labeling Machines

Bottles are fed and labeled automatically on conveyors

Suitable for high-speed production lines

High output, precise alignment, reduced labor needs

4. Rotary Labeling Machines

Designed for ultra-high-speed lines

Uses a carousel system to label multiple bottles simultaneously

Often used in beverages, pharma, and cosmetics industries

5. Shrink Sleeve Labeling Machines

Applies shrink labels using heat tunnels for 360° branding

Common in juice, soft drinks, and energy drink packaging

Applications of Bottle Labeling Machines

Food & Beverage Industry

Juices, mineral water, milk, sauces, syrups, oils, alcohol

Date coding, branding, and compliance labels

Pharmaceuticals

Tablets, syrups, liquid drugs

Includes batch number, expiry date, and dosage information

Cosmetics & Personal Care

Shampoos, conditioners, lotions, perfumes

Requires visually appealing labels to reflect brand identity

Chemicals and Agro-Products

Fertilizers, pesticides, cleaning products

Requires resistant, long-lasting adhesive labels

Core Features of Advanced Bottle Labeling Machines

1. High Labeling Speed

Capable of labeling 20 to 300 bottles per minute, depending on model and label type.

2. Accuracy and Precision

Label placement tolerance as low as ±1 mm, ensuring professional appearance.

3. Label Sensor System

Automatically detects label gaps and bottle positions to prevent misalignment.

4. Adjustable Conveyor System

Compatible with a wide range of bottle sizes and shapes.

5. Integrated Coding Devices

Allows real-time printing of batch numbers, barcodes, and expiry dates.

6. PLC and Touchscreen Control

Easy programming, operation, and error diagnostics through HMI systems.

Benefits of Using a Bottle Labeling Machine

Enhanced Branding: Professionally applied labels elevate product appeal

Time-Saving: Speeds up production lines exponentially

Reduced Human Error: Increases labeling accuracy and consistency

Compliance Assurance: Meets global labeling standards (FDA, FSSAI, EU)

Versatility: One machine can handle different bottle types and label formats

Low Operational Costs: Cuts labor costs while boosting throughput

0 notes

Text

VIDEOJET PRINTING INK Compatibility with Modern Coding Technologies

In today’s fast-paced industrial environment, reliable coding and marking solutions are essential for maintaining efficiency, compliance, and product traceability. One of the leading names in this space is VIDEOJET PRINTING INK, known for its outstanding performance across a wide range of production needs. As modern coding technologies continue to evolve, the compatibility of VIDEOJET PRINTING INK with these advanced systems plays a crucial role in enhancing operational workflows and ensuring high-quality output.

Let’s explore how VIDEOJET PRINTING INK seamlessly integrates with modern coding technologies and why it remains a preferred choice across industries.

Meeting the Demands of Evolving Coding Systems

Modern coding technologies have rapidly advanced to support higher production speeds, diverse substrates, and more stringent compliance requirements. Whether it's continuous inkjet (CIJ), thermal inkjet (TIJ), laser marking, or large character printing (LCP), every technology demands ink formulations that are optimized for specific applications.

VIDEOJET PRINTING INK is designed with compatibility in mind. It works effectively across multiple coding systems, especially with CIJ and TIJ printers, which are widely used in industries like food & beverage, pharmaceuticals, cosmetics, and electronics. Its superior adhesion properties and quick-drying characteristics make it suitable for a variety of materials such as glass, plastic, cardboard, and metals — all without compromising print clarity.

Precision and Consistency Across Substrates

The success of any modern coding solution relies heavily on consistent, legible prints — even on complex or irregular surfaces. VIDEOJET PRINTING INK is specially formulated to deliver high-contrast codes on challenging substrates, including slick plastic bottles, coated cartons, and flexible packaging.

For instance, when used with thermal inkjet printers, VIDEOJET PRINTING INK can produce high-resolution prints suitable for detailed information like QR codes, barcodes, and batch numbers. This level of precision ensures products meet regulatory and supply chain requirements without costly rework or delays.

Compatibility with Automation and Smart Production Lines

As Industry 4.0 and smart manufacturing trends continue to reshape factories, VIDEOJET PRINTING INK proves its adaptability by integrating seamlessly with automated systems. Today’s coding technologies often feature built-in software for remote monitoring, predictive maintenance, and real-time data tracking.

Whether integrated into robotic arms or smart conveyors, VIDEOJET-compatible printers and ink cartridges can work in sync with automated lines to minimize downtime and improve traceability. The chemical stability of VIDEOJET PRINTING INK ensures that the ink does not dry out or clog the printer even during extended idle times — a key advantage in automated environments.

Supporting Eco-Friendly and Regulatory Needs

Sustainability and compliance have become top priorities in modern manufacturing. VIDEOJET PRINTING INK is available in a range of formulations, including low-VOC (Volatile Organic Compounds) and MEK-free options, making it environmentally safer while still delivering strong performance.

Moreover, these inks comply with international safety and packaging regulations, including FDA, RoHS, and REACH standards, making them ideal for food, beverage, and pharmaceutical packaging. Modern coding technologies often come equipped with ink usage monitoring features, and VIDEOJET’s efficient ink formulations help reduce waste and operating costs over time.

Easy Integration with a Wide Range of Printers

One of the greatest strengths of VIDEOJET PRINTING INK is its wide printer compatibility. It is engineered to work perfectly with Videojet’s own series of printers, including the popular 1000 Line CIJ printers, 8510 TIJ printers, and more. This ensures plug-and-play functionality and optimal performance from the first print to the last.

For companies using a mix of legacy and new printing equipment, the versatility of VIDEOJET PRINTING INK provides a unified solution without the need for multiple ink inventories. This not only simplifies operations but also reduces maintenance and training time for machine operators.

Why Manufacturers Trust VIDEOJET PRINTING INK

Manufacturers around the globe rely on VIDEOJET PRINTING INK for its unmatched reliability, durability, and adaptability. Whether it's high-speed bottling lines or precise electronics labeling, this ink continues to deliver consistent results that keep operations running smoothly.

At SH HITECH SOLUTIONS, we understand how critical it is to choose the right ink for the right technology. That’s why we recommend VIDEOJET PRINTING INK for businesses looking to future-proof their production lines with high-performance, compatible ink solutions.

Final Thoughts

As coding technologies become smarter, faster, and more complex, the demand for high-performance inks that can keep up has never been greater. VIDEOJET PRINTING INK rises to the challenge, offering exceptional compatibility with modern coding technologies, from CIJ to TIJ and beyond.

For manufacturers seeking to streamline operations, maintain compliance, and ensure reliable product identification, VIDEOJET PRINTING INK remains a leading solution that supports both today’s needs and tomorrow’s innovations.

0 notes

Text

High-Strength Ready Mix Concrete for Commercial Use in Pakistan

In the evolving world of construction, the demand for reliable, durable, and cost-effective building materials has never been higher. Whether it's high-rise commercial complexes, shopping malls, industrial facilities, or infrastructure development, one critical element lies at the heart of every successful project: concrete. In Pakistan’s booming construction sector, Ready Mix Concrete in Pakistan is quickly becoming the go-to solution for modern builders. At the forefront of this transformation is Allied Materials, a trusted name synonymous with quality, consistency, and high-performance concrete solutions tailored for commercial use. We explore why Allied Materials is setting new benchmarks for ready mix concrete in Pakistan, and how businesses, contractors, and developers are benefiting from this advanced construction material.

What Is Ready Mix Concrete?

Ready Mix Concrete (RMC) is a specialized form of concrete that is manufactured in a controlled environment—typically a batching plant—and then delivered to construction sites in a ready-to-use form. Unlike traditional on-site mixing, RMC is prepared using precise proportions of cement, water, aggregates, and admixtures to meet specific strength and performance requirements.

This form of concrete eliminates the margin of error associated with manual mixing, ensuring consistency in quality and performance across batches—something every commercial project demands.

The Need for High-Strength Concrete in Commercial Projects

In commercial construction, concrete quality isn’t just a technical detail—it’s a fundamental requirement.

Why?

Structural Loads: Commercial buildings often need to withstand heavier loads than residential structures.

Durability: High-traffic areas like malls, warehouses, and offices demand concrete that can resist wear and tear.

Safety Compliance: Government regulations and engineering codes in Pakistan require specific strength levels in commercial structures.

Efficiency: Delays and inconsistencies in concrete delivery can slow progress and increase costs.

This is where Allied Materials delivers a game-changing solution with its high-strength Ready Mix Concrete in Pakistan.

Leading the Way in RMC Innovation

As one of the leading producers of ready mix concrete, Allied Materials combines cutting-edge technology, skilled manpower, and deep industry knowledge to produce concrete that meets the highest performance standards.

Here’s why Allied Materials stands out:

1. Precision in Mix Design

Every commercial project has its own unique structural requirements. Allied Materials’ expert engineers develop custom mix designs tailored to the compressive strength, workability, and setting time required for each application.

From M20 to M60+ concrete grades, Allied provides ready mix solutions for:

Commercial plazas

Warehouses and factories

Bridges and overpasses

Airport terminals

Office buildings and IT parks

2. Advanced Batching Technology

Allied Materials operates state-of-the-art batching plants that follow international standards. These facilities are equipped with:

Automated batching systems

Calibrated mixers and conveyors

High-efficiency aggregate handling systems

Moisture sensors and quality-control devices

This ensures every batch of concrete is identical in quality—delivered fresh, on time, and ready to pour.

3. Rigorous Quality Control

What sets Allied apart is its dedicated quality assurance team. Each batch of concrete undergoes comprehensive testing at every stage:

Slump test for workability

Cube testing for compressive strength

Setting time and curing analysis

Water-cement ratio control

This rigorous quality monitoring ensures the concrete not only meets but exceeds project specifications.

4. Logistics That Never Let You Down

Commercial projects can’t afford downtime. With a well-maintained fleet of transit mixers and boom pumps, Allied ensures:

Timely delivery to sites across Pakistan

Concrete is transported under controlled conditions

Minimization of delays, material loss, and rework

This reliability keeps your construction schedule on track and your budget under control.

Benefits of Using Ready Mix Concrete in Pakistan for Commercial Construction

Choosing ready mix concrete in Pakistan through Allied Materials offers numerous advantages for commercial developers and builders.

1. Consistency

RMC offers unparalleled consistency in strength, texture, and workability—ensuring predictable results for engineers and contractors.

2. Speed of Construction

No more wasting time mixing on-site. With Allied’s RMC, concrete arrives ready to pour—helping you meet tight deadlines and avoid unnecessary delays.

3. Labor and Cost Efficiency

Less manpower is needed for mixing and quality control. This reduces labor costs and boosts overall efficiency.

4. Environmental Benefits

RMC minimizes dust, noise, and onsite waste, making it an eco-friendly alternative for modern, sustainable construction practices.

5. Custom Solutions

Allied offers tailored RMC solutions depending on your structural load, design, and environmental conditions.

Commercial Use Cases of Allied Materials' Ready Mix Concrete

1. Shopping Malls & Retail Complexes Allied’s RMC provides the structural integrity required for large, multi-story malls with heavy foot traffic and load-bearing requirements.

2. Office Buildings & Business Centers From foundations to roofs, high-grade RMC ensures long-term durability and fast-paced construction in commercial zones.

3. Industrial Facilities & Warehouses Allied delivers high-compression mixes ideal for floors that bear the weight of machinery, forklifts, and constant movement.

4. Infrastructure Projects Allied has provided concrete for bridges, roads, metro stations, and drainage systems where precision and resilience are paramount.

Allied’s Commitment to Innovation and Sustainability

Allied Materials is not just a concrete supplier—it’s a construction partner committed to innovation, safety, and environmental stewardship.

Sustainable Practices Include:

Use of recycled aggregates

Water reuse systems at batching plants

Dust suppression and emission control mechanisms

Green fleet initiatives to reduce carbon emissions

This aligns with Pakistan’s growing emphasis on sustainable urban development and smart city initiatives.

How to Order Ready Mix Concrete from Allied Materials

Ordering concrete with Allied is simple and streamlined:

Step 1: Visit the Website

Go to Ready Mix Concrete in Pakistan and fill out a quick inquiry form.

Step 2: Get Consultation

Discuss your project requirements with Allied’s technical team.

Step 3: Receive a Customized Quote

Get competitive pricing tailored to your project’s scale and concrete grade needs.

Step 4: Schedule and Delivery

Set a delivery schedule based on your construction timeline.

Step 5: Enjoy On-Site Technical Support

Allied provides onsite assistance to ensure proper handling, pouring, and curing of concrete.

Conclusion

For commercial construction in Pakistan, success hinges on speed, safety, and structural integrity. Choosing Ready Mix Concrete in Pakistan from Allied Materials isn’t just a smart choice—it’s a strategic investment in your project's success. With its focus on quality, innovation, sustainability, and customer satisfaction, Allied is redefining how commercial construction is done in Pakistan. Whether you're building a corporate plaza in Karachi, a shopping mall in Lahore, or a logistics hub in Islamabad Allied is your trusted partner from foundation to finish.

0 notes

Text

Unwrap - Le Classico (Choco Rolls)

Gift Hampers| Premium Chocolate Gifts| Cookies Gift Boxes| Unwrap Happiness| Dry Fruits Hampers| Wafer Sticks| Online| Snacks Gift Hampers| Products| Occasions Hampers| Customized Gifts| Premium Herbal Teas

Unwrap Happiness curates exquisite confections that honor India’s rich culinary heritage with a refined global twist. From handpicked ingredients to artful packaging, every hamper is a luxurious expression of taste, tradition, and thoughtfulness—perfect for festive moments, corporate elegance, or personal indulgence.

Manufacturing Process: Le Classico Choco Rolls

Ingredient Preparation

High-quality ingredients like refined wheat flour, cocoa powder, butter, and sugar are precisely measured.

Cocoa paste and chocolate compounds are melted and tempered to ensure smooth texture.

Dough Mixing

A rich, soft dough is created by blending flour, fats, sugar, and a chocolate essence base.

The dough is aerated slightly to maintain a soft bite post-baking.

Sheeting & Rolling

The dough is sheeted to a uniform thickness and filled with luscious chocolate crème or ganache.

Rolled carefully into classic Swiss-roll style cylinders or spiral forms.

Baking

Rolls are baked at optimal temperature to maintain softness while ensuring stability and shelf life.

Cooling is done on a conveyor belt to avoid condensation inside the packaging.

Coating (Optional)

Rolls may be enrobed in a silky chocolate coating or dusted with cocoa powder or icing sugar.

Packaging

Individually wrapped using moisture-proof packaging to preserve freshness and prevent melting.

Final boxes are quality-checked, batch-coded, and sealed for shipment.

Key Ingredients

Refined Wheat Flour (Maida)

Sugar

Cocoa Powder

Chocolate Compound or Coverture

Butter or Vegetable Fat

Milk Solids

Emulsifiers (e.g., lecithin)

Natural & Artificial Flavors (vanilla, cocoa)

Baking Powder / Baking Soda

Salt

Preservatives (as per shelf-life requirements)

Available & Suggested Flavors

Classic Choco Fudge

Rich chocolate sponge with a creamy fudge center.

Hazelnut Delight

Chocolate roll with a smooth hazelnut cocoa filling.

Mocha Swirl

Coffee-infused chocolate sponge with mocha crème.

Dark Fantasy

Intense dark chocolate sponge with bitter-sweet ganache.

Choco Orange Zest

Chocolate sponge paired with a citrusy orange filling.

Almond Crunch

Filled with almond praline paste and bits of roasted almonds.

Berry Cocoa Bliss (seasonal)

Chocolate sponge with raspberry or strawberry infused crème.

For More Details: https://www.unwraphappiness.in/

#cookies gift hampers#herbal tea#chocolate gift hampers#snacks gift hampers#wafers sticks#wedding gift hampers#festival gift hampers#dryfruits#customized gifts#Online#Products

0 notes

Text

Applications of Paste Filling Machines in Food, Pharma & Cosmetics

Lodha International LLP is a leading Manufacturer of Paste Filling Machine. In today's fast-paced manufacturing environment, precision, hygiene, and speed are critical across sectors such as food, pharmaceuticals, and cosmetics. One indispensable piece of equipment that supports these goals is the Paste Filling Machine. Whether it's thick creams, viscous gels, toothpaste, or pharmaceutical ointments, these machines offer consistent volume filling with minimal wastage. Companies looking to maintain quality and improve production efficiency heavily rely on the Automatic Paste Filling Machine.

We have developed high-quality Paste Filling Machines to meet modern industrial demands. With robust engineering, user-friendly controls, and adaptable filling heads, our equipment has found applications worldwide. From cosmetic jars to pharmaceutical tubes and food containers, our machines provide seamless solutions that combine automation with high performance.

What is a Paste Filling Machine?

A Paste Filling Machine is a type of volumetric filling equipment designed specifically for viscous or semi-viscous products. Unlike standard liquid fillers, it accommodates materials that require pressure-assisted flow and precise dispensing. These machines are typically used for filling:

Toothpaste

Creams and gels

Ointments and balms

Adhesives

Gums and jellies

Cosmetic pastes

Sauces and condiments

The primary mechanism involves a piston system or rotary valve that draws the paste into a chamber and then pushes it out into the packaging container. The use of stainless-steel components makes the system highly durable and compliant with hygiene standards.

Working Principle of the Automatic Paste Filling Machine

The Automatic Paste Filling Machine from Lodha International LLP operates on the volumetric filling principle using a rotary valve-type piston mechanism. Here's how it works:

Material Loading: Product is loaded into a stainless-steel hopper.

Rotary Valve Activation: The rotary valve directs the paste into the piston chamber.

Piston Movement: The piston retracts to draw the paste and then pushes it forward.

Nozzle Dispensing: The material is dispensed through a positive shut-off nozzle to prevent dripping.

Container Handling: The conveyor belt positions each container precisely under the filling nozzle.

Lifting Mechanism: The lifting system adjusts container height to align with the nozzle.

This sequence repeats automatically, with adjustable parameters for volume, speed, and fill cycle.

Features of Lodha's Automatic Paste Filling Machine

Our Automatic Paste Filling Machine incorporates the following features:

SS-304 or SS-316 contact parts for enhanced durability

Rotary valve design for precision and drip-free operation

Positive shut-off nozzles

Easy-to-adjust fill volumes with stroke limiter

Conveyor system powered by A/C motors with variable drives

Pneumatic and electrical controls for accuracy

Compact and freestanding frame design

Optional coding system for post-fill batch marking

These features make it the ideal choice for manufacturers needing high-speed, low-maintenance, and scalable filling solutions.

Benefits of Using Paste Filling Machines

Here are the core benefits of adopting a Paste Filling Machine for industrial production:

High Fill Accuracy: Up to ±1% tolerance

Reduced Waste: Efficient dispensing minimizes material loss

Scalability: Suitable for small batches and mass production

Consistent Results: Volumetric control ensures uniform output

Versatility: Compatible with different container shapes and paste types

Ease of Cleaning: Stainless steel surfaces support rapid cleaning and sanitation

Automation Friendly: Integrates easily with labeling, sealing, and capping machines

Why Choose Us

Lodha International LLP is a trusted name in the machinery manufacturing industry for good reason. With years of experience and a customer-first philosophy, we build machines that perform reliably across industries. Our Paste Filling Machines are not only robust and user-friendly but also designed with the latest technology in mind. From manufacturing to after-sales support, our team is committed to delivering value at every step. If you are looking for consistency, performance, and longevity in your paste filling systems, Lodha International LLP is the partner to trust.

Conclusion

The Paste Filling Machine plays an indispensable role in multiple industries—from pharmaceuticals and cosmetics to food and beverages. Its ability to deliver consistent, accurate filling of viscous materials makes it a must-have for modern manufacturers. With hygienic design, customizable features, and scalable performance, this equipment enhances both quality and efficiency. Partnering with Lodha International LLP means accessing a world of advanced engineering and reliable service that supports your business growth. Choose the right machinery, streamline your operations, and lead your market with technology that works.

For more information about Paste Filling Machines, call us at +91 9687731331 or email us at [email protected]. Learn how Lodha International LLP can optimize your filling process today.

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

How Does an Automatic Pouch Packaging Machine Work?

In today’s fast-paced industrial landscape, packaging plays a crucial role in ensuring product safety, enhancing shelf appeal, and improving overall efficiency. Businesses across various industries rely on Automatic Pouch Packaging Machines to streamline their production lines and maintain product quality. But how do these machines function? Let’s explore the working process of an Automatic Pouch Packaging Machine and why choosing a reliable Automatic Pouch Packaging Machine Manufacturer like Ambika Packaging Solution is essential.

Understanding Automatic Pouch Packaging Machines

An Automatic Pouch Packaging Machine is a high-speed, precision-based equipment designed to fill and seal pouches efficiently. These machines are widely used in industries such as food & beverage, pharmaceuticals, chemicals, cosmetics, and more. By automating the packaging process, businesses can achieve greater consistency, reduce labor costs, and increase productivity.

Step-by-Step Working Process of an Automatic Pouch Packaging Machine

1. Pouch Loading and Feeding

The process starts with pouch loading, where pre-formed pouches are fed into the machine. Some machines come with an automatic feeding system that picks up the pouches from a stack and places them into the designated position for further processing.

2. Pouch Detection and Alignment

Once the pouches are fed into the system, sensors detect their presence and ensure proper alignment. This step is critical to avoid errors such as misaligned sealing or improper filling, which could compromise the packaging quality.

3. Pouch Opening

After alignment, the machine opens the pouch using vacuum suction or mechanical grippers. This step ensures that the pouch is fully open and ready to receive the product without any obstructions.

4. Product Filling

The filling station dispenses the pre-measured product into the open pouch. Different types of filling mechanisms are used depending on the nature of the product:

Auger Fillers – Used for powders like spices, flour, and coffee.

Liquid Fillers – Ideal for juices, oils, and sauces.

Weigh Fillers – Used for granular and solid products like snacks, nuts, and dry fruits.

5. Excess Air Removal (Optional)

In some packaging processes, excess air is removed from the pouch to increase product shelf life and maintain freshness. This is especially important in food packaging.

6. Pouch Sealing

Once the product is filled, the pouch moves to the sealing station. The machine applies heat and pressure to seal the pouch effectively. There are different sealing techniques, such as:

Heat Sealing – Commonly used for plastic and laminated pouches.

Ultrasonic Sealing – Used for delicate packaging materials and provides a strong seal without excessive heat.

7. Coding and Labeling (Optional)

Many Automatic Pouch Packaging Machines integrate a coding system to print batch numbers, manufacturing dates, expiration dates, and barcodes on the pouch. This step ensures compliance with industry regulations and enhances traceability.

8. Pouch Cutting and Discharge

After sealing, the machine cuts the pouch to separate it from the next one (if applicable) and then discharges the finished product onto a conveyor belt or collection area for final inspection and packaging.

9. Quality Check and Sorting

A final quality check ensures that the pouches are properly sealed, labeled, and free from defects. Any defective pouches are rejected automatically to maintain the highest packaging standards.

Benefits of Using an Automatic Pouch Packaging Machine

Increased Efficiency – Automating the packaging process significantly reduces downtime and improves production speed.

Consistent Quality – Ensures uniform filling, sealing, and packaging, eliminating human errors.

Reduced Labor Costs – Minimizes the need for manual intervention, cutting down labor expenses.

Versatility – Can handle a variety of pouch materials, shapes, and sizes.

Enhanced Product Shelf Life – Proper sealing techniques help prevent contamination and spoilage.

Customization Options – Machines can be tailored to suit specific industry requirements.

Choosing the Right Automatic Pouch Packaging Machine Manufacturer

Selecting a reliable Automatic Pouch Packaging Machine Manufacturer is crucial for ensuring durability, efficiency, and quality. Ambika Packaging Solution is a trusted name in the industry, offering state-of-the-art packaging machines tailored to various industrial needs. Here’s why you should choose Ambika Packaging Solution:

Advanced Technology – They use cutting-edge technology to manufacture high-performance packaging machines.

Customization – They provide tailored solutions to meet specific business requirements.

Quality Assurance – Machines undergo rigorous quality checks to ensure reliability and efficiency.

After-Sales Support – Dedicated customer support ensures seamless operation and minimal downtime.

Industry Expertise – Years of experience in the packaging industry make them a preferred choice among businesses.

Conclusion

An Automatic Pouch Packaging Machine is a game-changer for industries looking to enhance efficiency and maintain high packaging standards. By automating the pouch filling and sealing process, businesses can achieve consistent quality, reduce costs, and increase productivity. Choosing a reliable Automatic Pouch Packaging Machine Manufacturer, such as Ambika Packaging Solution, ensures that you get a high-quality machine tailored to your industry needs.

If you’re looking for a trusted partner in packaging automation, Ambika Packaging Solution offers cutting-edge solutions to streamline your packaging operations. Contact them today to learn more about their innovative packaging machines!

#Automatic Pouch Packaging Machine Manufacturer#Packaging Solutions Near Me#Packaging Machine Manufacturer in Haryana#Liquid Packaging Machines Manufacturer

0 notes

Text

Sticker Labelling Machine: The Complete Guide to Smart Product Labeling

What is a Sticker Labelling Machine?

A sticker labelling machine is a device that applies pre-printed or blank self-adhesive labels (commonly called "stickers") onto various products like bottles, jars, boxes, and containers. These machines offer precision, speed, and customization for diverse packaging requirements.

They eliminate the inefficiencies of manual labeling and ensure that labels are applied straight, bubble-free, and uniformly across thousands of items daily.

Types of Sticker Labelling Machines

1. Manual Sticker Labelling Machines

Best for small-scale production

Cost-effective and simple to operate

Ideal for startups and cottage industries

2. Semi-Automatic Sticker Labelling Machines

Operator loads the product manually; machine applies the label

Perfect for medium-volume operations

Common in the food, personal care, and small pharmaceutical sectors

3. Automatic Sticker Labelling Machines

Fully automated with conveyor belt integration

High-speed labeling with minimal human intervention

Used for mass production and industrial packaging lines

4. Double Side Sticker Labelling Machines

Labels both the front and back sides of containers simultaneously

Excellent for cosmetics, shampoos, and cleaning products

5. Wrap Around Sticker Labelling Machines

Designed for cylindrical bottles and jars

Applies a full 360° label

6. Top and Bottom Labelling Machines

Apply stickers to top and/or bottom surfaces of flat objects like boxes, trays, and pouches

Industrial Applications of Sticker Labelling Machines

Pharmaceutical Industry

Applies labels with dosage, expiry date, QR codes

Ensures regulatory compliance and barcode readability

Food and Beverage

Bottle and jar labeling for soft drinks, sauces, honey, and oils

Labels withstand refrigeration and moisture exposure

Cosmetic Industry

High-end product labeling for creams, serums, and perfumes

Requires elegant, smudge-free, and durable finishes

Chemical and Pesticide Industry

Labels resistant to harsh chemicals, UV, and abrasion

Logistics and Warehousing

Barcode labels, shipping tags, inventory stickers

Key Features of a Modern Sticker Labelling Machine

1. High-Speed Operation

Capable of labeling 100 to 400 units per minute, depending on model

2. Advanced Sensor Systems

Detects product presence and label gaps for precise placement

3. Touchscreen HMI and PLC Controls

Easy configuration, error detection, and real-time production monitoring

4. Adjustable for Multiple Products

Handles various diameters, shapes, and label sizes

5. Coding and Printing Integration

Supports batch coding, barcodes, QR codes, manufacturing/expiry dates

6. Stainless Steel Construction

Food and pharma-grade SS304/SS316 material ensures hygiene and durability

Advantages of Using Sticker Labelling Machines

Professional Finish: Ensures brand consistency across all units

Enhanced Productivity: Reduces labeling time drastically

Cost Efficiency: Cuts down on labor and label waste

Minimal Downtime: Easy to maintain and calibrate

Customizable: Adapts to various products and packaging formats

Regulatory Compliance: Meets FDA, FSSAI, ISO standards for packaging

0 notes

Text

High-Performance Domino Batch Coding Machine for Packaging Lines

The Domino Batch Coding Machine offers exceptional performance and print quality, tailored for automated and high-volume packaging operations. Designed to integrate seamlessly with conveyor systems and production lines, this machine delivers crisp, accurate coding at high speeds. It supports a variety of inks and substrates, making it a versatile choice for coding on plastics, glass, metal, and paper. With smart control features, real-time diagnostics, and long-lasting reliability, the Domino Batch Coding Machine enhances operational efficiency while reducing downtime and waste.

0 notes

Text

Effortless PLC Programming Using CODESYS at Servotech

Introduction

In today’s fast-paced industrial automation landscape, efficient and user-friendly PLC programming is crucial for optimizing processes and reducing downtime. Servotech, a leader in automation solutions, leverages CODESYS to simplify PLC programming, making it more accessible and streamlined. Whether you are an experienced engineer or a novice, programming with CODESYS at Servotech ensures effortless integration, flexibility, and efficiency.

What is CODESYS?

CODESYS (Controller Development System) is a software platform designed for industrial automation, providing an integrated development environment (IDE) for programming PLCs and other control devices. It supports multiple IEC 61131-3 programming languages, including:

Ladder Diagram (LD)

Structured Text (ST)

Function Block Diagram (FBD)

Instruction List (IL)

Sequential Function Chart (SFC)

Continuous Function Chart (CFC)

CODESYS is hardware-independent, allowing it to be used across various controllers, making it a versatile and scalable solution for industries.

Why Choose CODESYS for PLC Programming at Servotech?

1. User-Friendly Interface

CODESYS provides an intuitive and graphical environment, making PLC programming easier. Engineers at Servotech benefit from an integrated project tree, drag-and-drop functionality, and seamless code visualization, reducing programming complexity.

2. Hardware Independence

Unlike traditional PLC software, CODESYS is not tied to specific hardware. This means that Servotech can use a variety of controllers, reducing costs and increasing flexibility in automation solutions.

3. Multi-Language Support

The ability to switch between different IEC 61131-3 languages allows programmers to choose the best approach for their application, ensuring efficient code development.

4. Powerful Debugging and Simulation Tools

CODESYS includes a real-time debugging environment, simulation tools, and diagnostics, which enable Servotech engineers to test and refine PLC programs without deploying them directly on hardware.

5. Seamless Integration with HMI and SCADA

CODESYS supports Human Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA) systems, allowing for comprehensive process control and monitoring.

Step-by-Step Guide to PLC Programming with CODESYS at Servotech

Step 1: Setting Up the CODESYS Environment

Install CODESYS IDE on a Windows-based system.

Configure the target PLC hardware (if applicable) or use a virtual PLC.

Step 2: Creating a New Project

Launch CODESYS and select New Project.

Choose the desired PLC type and programming language (LD, ST, FBD, etc.).

Step 3: Defining Inputs and Outputs (I/O)

Set up digital and analog inputs/outputs in the project tree.

Assign appropriate tags to sensors, actuators, and communication interfaces.

Step 4: Writing the PLC Logic

Use Ladder Logic (LD) for simple control processes.

Implement Function Block Diagram (FBD) for graphical logic representation.

Use Structured Text (ST) for complex calculations and conditions.

Step 5: Simulating and Debugging

Run offline simulation to verify logic and troubleshoot errors.

Utilize breakpoints and variable monitoring to optimize program execution.

Step 6: Deploying the Program

Download the finalized PLC program onto the Servotech automation system.

Test real-time performance and adjust parameters as needed.

Applications of CODESYS-Based PLC Programming at Servotech

1. Factory Automation

Assembly line automation

Conveyor belt control

Material handling systems

2. Process Control

Temperature and pressure regulation

Fluid flow monitoring

Batch processing in manufacturing

3. Building Automation

Smart lighting control

HVAC system automation

Security and access control

4. Renewable Energy Systems

Solar and wind energy management

Battery storage optimization

Grid integration solutions

Advantages of CODESYS at Servotech

Cost-Effective Development

CODESYS eliminates the need for expensive proprietary software, making it a cost-efficient solution for Servotech’s automation needs.

Scalability and Modularity

Servotech can use CODESYS across multiple projects, scaling from small automation tasks to large industrial control systems.

Community Support and Updates

With an active global community and regular updates, CODESYS remains up-to-date with the latest industrial trends, ensuring future-proof automation.

Conclusion

CODESYS has revolutionized PLC programming at Servotech, providing an effortless, cost-effective, and flexible automation solution. Its hardware independence, user-friendly interface, powerful debugging tools, and multi-language support make it the ideal choice for modern industrial applications. By adopting CODESYS, Servotech continues to lead the way in smart automation, delivering high-performance control solutions for diverse industries.

0 notes

Text

Packaging Automation Solutions: A Game-Changer for Modern Businesses

Automation is no longer just a buzzword; it’s the lifeblood of industries striving for efficiency and innovation. In the world of packaging, packaging automation solutions are transforming how businesses operate. From small startups to multinational giants, everyone is tapping into the power of automation to streamline processes and boost productivity. Let’s explore what makes these solutions so impactful, and yes, we’ll keep it engaging—because automation doesn’t have to be boring!

What Are Packaging Automation Solutions?

Packaging automation solutions encompass advanced technologies and systems designed to handle various packaging tasks—think filling, sealing, labeling, and palletizing—with minimal human intervention. These solutions use robotics, sensors, and software to deliver precision, speed, and reliability in packaging operations.

Gone are the days of endless manual labor on assembly lines. With packaging automation solutions, businesses can achieve more in less time, ensuring consistent quality while reducing costs.

Why Should Businesses Invest in Packaging Automation Solutions?

Let’s break it down:

Speed: Imagine meeting tight deadlines without breaking a sweat.

Accuracy: Say goodbye to crooked labels and messy seals.

Cost Savings: Less waste and reduced labor costs mean a better bottom line.

Scalability: Whether it’s 100 units or 10,000, automation adapts to your needs.

Happier Teams: Employees can focus on creative, meaningful tasks instead of repetitive grunt work.

The Benefits of Packaging Automation Solutions

1. Supercharged Productivity

With packaging automation solutions, what used to take hours can now be done in minutes. Machines don’t take breaks, and they certainly don’t call in sick. This consistent output ensures you meet production goals, even during peak demand periods.

2. Impeccable Quality Control

Human error is inevitable, but machines? They’re built for precision. Whether it’s filling bottles to the exact milliliter or applying labels perfectly every time, automation ensures your products look and perform their best.

3. Cost Efficiency

While the initial investment might seem steep, the long-term savings are worth it. Automation minimizes waste, optimizes material use, and reduces the need for manual labor. Over time, these savings add up significantly.

4. Enhanced Worker Safety

Let’s face it—packaging tasks can be repetitive and even hazardous. Packaging automation solutions take over the physically demanding jobs, reducing workplace injuries and keeping your team safe.

5. Eco-Friendly Operations

Modern automation systems are designed with sustainability in mind. They optimize resource use, reduce waste, and often integrate with green energy solutions, helping your business stay environmentally responsible.

How Do Packaging Automation Solutions Work?

Step 1: Feeding and Organizing

Products are fed into the system using conveyors and robotic arms. These machines organize and sort items, ensuring a smooth flow through the packaging line.

Step 2: Filling and Sealing

Automated systems precisely measure and fill products into containers, be it liquids, powders, or solids. Once filled, the packages are sealed—tight, secure, and ready to move on.

Step 3: Labeling and Coding

Labels are applied flawlessly, and any necessary information—like barcodes, batch numbers, or expiry dates—is printed with laser-sharp clarity.

Step 4: Quality Checks

AI-powered cameras and sensors inspect every package to ensure it meets quality standards. Defective products are flagged and removed from the line.

Step 5: Palletizing and Shipping

Finally, robotic arms stack the packaged goods onto pallets, optimizing them for storage or transport. Some systems even integrate with logistics software for seamless shipping.

Real-World Success Stories

Case Study 1: A Craft Brewery’s Leap to Automation

A small craft brewery struggling with demand spikes turned to packaging automation solutions. The result? Their production tripled, labor costs halved, and they finally had time to focus on brewing award-winning beers.

Case Study 2: A Global Retailer’s Packaging Overhaul

A retail giant adopted fully automated packaging systems across their distribution centers. Not only did this cut processing times by 60%, but it also reduced packaging waste by 30%, aligning with their sustainability goals.

Challenges in Adopting Packaging Automation Solutions

Initial Costs

Let’s be honest—automation isn’t cheap. Investment if often important as long-term benefits often outweigh the initial expenses.

Skill Gaps

Operating and maintaining automated systems require skilled workers. Investing in training is crucial.

Integration

Adapting new systems to existing operations can be tricky. Partnering with experienced providers ensures a smoother transition.

The Future of Packaging Automation Solutions

The future is bright, and it’s automated! Innovations in AI, machine learning, and IoT are making packaging systems smarter and more adaptable. Picture this: machines that predict maintenance needs, adapt to new packaging designs on the fly, and optimize energy use—all while keeping your operations running smoothly.

Conclusion

Packaging automation solutions are the secret sauce for businesses aiming to stay competitive in today’s fast-paced world. They enhance efficiency, improve quality, and save costs—all while making operations safer and more sustainable. Whether you’re a small startup or a global powerhouse, automation can revolutionize your packaging game. So, what are you waiting for? It’s time to let the robots take the reins—and maybe crack a joke or two along the way!

FAQs

1. What industries benefit the most from packaging automation solutions?

Virtually all industries—from food and beverages to pharmaceuticals, cosmetics, and e-commerce—can benefit from automation.

2. How long does it take to see ROI on automation?

Depending on the scale of implementation, most businesses see ROI within 1-3 years.

3. Is automation suitable for small businesses?

Absolutely! Scalable solutions mean even small businesses can adopt automation without breaking the bank.

4. Do automated systems require a lot of maintenance?

Regular maintenance is necessary but manageable, especially with modern systems designed for durability and self-diagnosis.

5. Can automation help with sustainability?

Yes! Many systems are designed to optimize resources and reduce waste, making your operations greener.

1 note

·

View note

Text

A Comparative Analysis for Variable Data Printing vs. Traditional Printing

The printing industry has seen significant advancements over the years, particularly with the introduction of variable data printing (VDP). This technology allows for the printing of individualized information on each sheet, such as alphanumeric characters, addresses, barcodes, QR codes, and logos.

What is Variable Data Printing?

Variable data printing (VDP) involves printing unique data on each sheet, which is crucial for applications requiring personalized information. This technology supports high-speed printing on various substrates like Colour Wove, Maplitho, Art Paper, Duplex Board up to 350 gsm, and NCR Sheet. The Autoprint Reckoner VDP65 is an example of a machine that leverages HP Inkjet Technology to offer efficient numbering, barcoding, mail addressing, and online perforation.

Traditional Printing

Traditional printing methods, such as offset and digital printing, produce identical copies of a print job. These methods are cost-effective for large volumes of the same print material but do not offer the flexibility of VDP. Traditional printing is best suited for mass production where the content remains consistent across all copies.

Advantages of Variable Data Printing

1. Personalization: VDP allows for the customization of each printed piece, making it ideal for direct mail, marketing materials, and personalized invitations.

2. Efficiency: By printing variable information directly, VDP eliminates the need for pre-printed stock and separate personalization steps, reducing production time.

3. Cost-Effectiveness: Although the initial setup cost may be higher, VDP can be more cost-effective in the long run by reducing waste and inventory costs.

4. Versatility: VDP can be applied to various substrates and formats, offering flexibility for different applications.

Autoprint Reckoner VDP65

The Autoprint Reckoner VDP65 is an offline sheetfed variable data printing machine using HP Inkjet Technology. It is designed for high-speed, accurate printing of variable data such as numbers, barcodes, and addresses. As an authorized oil-free air compressor dealer, AS Equipment ensures that customers receive top-quality products along with exceptional support and service, maximizing the performance and reliability of their compressed air systems.

Batch Coding Systems

A batch coding system is crucial for marking products with unique codes or batch numbers, ensuring traceability throughout the supply chain. These systems are vital for industries like food and beverage, pharmaceuticals, and cosmetics, where product safety and quality are paramount. Batch coding can be integrated with VDP machines to streamline processes and ensure accurate, consistent coding.

Steps Involved in Batch Coding

1. Prepare the Design: Create the design for the batch code, including relevant information such as the date of manufacture and product batch number.

2. Set Up the Machine: Calibrate the batch coding machine and load the necessary ink or ribbon.

3. Load the Product: Position the product or packaging correctly on the machine’s conveyor.

4. Set Parameters: Configure printing speed, number of copies, and other settings.

5. Start Coding: Activate the machine to print the batch code.

6. Verify Codes: Check the printed codes for accuracy and legibility.

Both variable data printing and traditional printing have their unique advantages and are suited to different applications. VDP offers unparalleled flexibility and efficiency for personalized printing needs, while traditional printing remains the best choice for large-scale, uniform print jobs. By understanding the strengths of each method, businesses can choose the right technology to optimize their production processes. For high-quality VDP solutions, the Autoprint Reckoner VDP65 stands out as a reliable choice, supported by AS Equipment’s excellent service as an authorized dealer.

Read more posts Maximizing Efficiency with Automatic UV Coating Machines: Tips and Best Practices Role of prepress in offset printing

0 notes

Text

Frequently Asked Questions(FAQs) about Ink Pumps for Continuous Inkjet Printers(CIJ)

You will find the following information here:

What is CIJ?

What is the primary application of continuous inkjet printers?

How does continuous inkjet printing work?

How is a continuous inkjet system formed?

Common issues with ink pumps in continuous inkjet printers

TOPSFLO CIJ ink pumps Solution

How to Get in Touch with TOPSFLO for Expert Assistance?

What is CIJ?

CIJ stands for Continuous Inkjet, CIJ is a small character inkjet printing technology that uses a single inkjet nozzle to rapidly spray ink into tiny droplets, forming printed images or text. CIJ printers are widely used worldwide and are a non-contact printing method, making them suitable for marking on both flat and curved surfaces. They are primarily used in industrial applications for product packaging, labeling, and coding.

What are the Main Applications of Continuous Inkjet Printers?

Continuous inkjet printers are primarily used to mark production dates, batch numbers, barcodes, and other information on the surfaces of various materials such as plastic, metal, glass, cardboard, and wood. Typical applications include beverage cartons, cans, and bags, pharmaceuticals, small cardboard boxes, cables, and components. Virtually any product or packaging that moves on a conveyor belt or extrusion machine is suitable for continuous inkjet printing.

How does Continuous Inkjet Printers Work?

Continuous inkjet printers create a continuous stream of ink, which is broken down into numerous ink droplets through high-frequency vibrations. Once the ink droplets are formed, the selected ones are charged by electrodes and then directed by a deflection plate that generates an electrostatic field.

Charged ink droplets pass through the deflection plate, causing them to deviate at a specific angle before being sprayed from the print head onto the product to create the desired printed information. Uncharged ink droplets remain unaffected and return directly to the CIJ ink system.

During this printing process, the solvent base of the ink evaporates, and the viscosity of the ink changes accordingly. To ensure the optimal droplet formulation, viscosity must be strictly controlled within specified values.

How is a Continuous Inkjet System Formed?

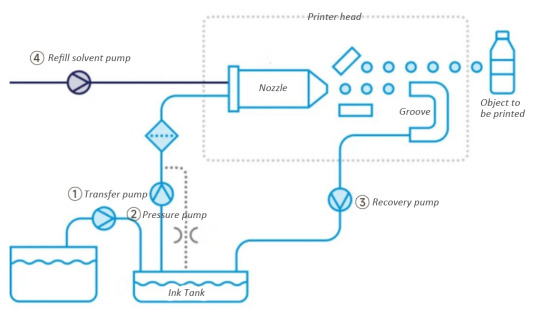

In continuous inkjet (CIJ) printing, ink circulates continuously throughout the printer, from the fluid system to the printhead, and then back to the fluid system. The entire ink path system involves several pumps working in coordination.

Initially, ink is transported from a large container to an ink reservoir using a transfer pump (①).

Subsequently, the ink is pressurized and transferred to the printhead using a pressure pump (②). Inside the printhead, the ink flows through nozzles, forming a continuous array of small ink droplets, each of which can be individually charged. Charged droplets are deflected by electrodes and hit the object to be printed.

Additionally, uncharged ink droplets fly in a straight line into a gutter, and excess ink is recirculated from this point back to the ink reservoir using a recirculation/suction/recovery pump (③).

To prevent the ink from drying and damaging the system when the printer is not in use, a refill solvent pump (④) is typically included in the continuous inkjet system. This pump delivers solvent to the nozzles to flush out any residual ink.

Through these steps, a continuous inkjet system can continuously supply ink and achieve high-speed, efficient inkjet printing.

Common Issues with Ink Pumps in Continuous Inkjet Printers

1. In the current market, there is a wide variety of ink types used in CIJ printers, each with different viscosities. These different ink compositions may contain additives, some of which can be corrosive, leading to compatibility issues with pump materials that can cause malfunctions or a very short lifespan.

2. Instability in the liquid circuit pressure and ink flow during the operation of the inkjet printer can affect the printing results.

Continuous inkjet printing requires prolonged periods of operation. Over time, continuous use may result in wear and tear, potentially leading to a decline in performance or malfunctions, thus compromising the printer's lifespan.

TOPSFLO CIJ ink pumps Solution

Diverse Pump Materials

Topsflo printer ink pumps offer a variety of pump material configurations to accommodate common CIJ ink types, such as MEK, dye-based inks, pigment inks, and soft pigment inks. The pump head materials for diaphragm pumps can be selected from PA, PPS, or PP, while membrane materials can be chosen from EPDM or PTFE. For valve materials, options include EPDM, FKM, or FFKM. YT alloy gear pumps are mainly used for pigment inks, while PEEK gears can be used for dye-based inks.

Carefully Selected Pump Types for Precise Applications

Topsflo offers two pump options tailored for printer applications: diaphragm pumps and gear pumps.

- Diaphragm liquid pumps, especially those designed for low-flow rates, provide relatively stable flow and pressure output. They are more suitable for handling liquids containing solid particles or particulate matter because their design is better suited for handling suspended particles. However, in high-flow applications, diaphragm pumps may produce larger pulses, which could lead to vibration or noise issues.

- Gear pumps are suitable for printers that require a large volume of ink. They offer stable flow and pressure output with lower pulsation. Compared to ordinary gear pumps on the market, TOPSFLO gear pumps use high-precision gears and component control to ensure smooth flow, minimal pulsation, and adjustable output pressure stability.

TOPSFLO engineers can determine which pump is better suited for your application based on your printing requirements, including the desired flow rate, accuracy, pulsation, noise level, ink properties, and whether they contain solid particles, among other factors.

Long-lasting Lifetime for Stable Printing Assurance

Both Topsflo diaphragm pumps and gear pumps are equipped with high-performance brushless motors developed in-house.

The coreless brushless motor in the diaphragm pump boasts a lifespan of up to 15,000 hours, while the gear pump utilizes a high-performance, in-house designed and manufactured brushless three-phase motor with a lifespan exceeding 30,000 hours, requiring no maintenance.

These brushless motors do not produce sparks, static electricity, or electromagnetic interference during operation, ensuring safety and allowing the pumps to run continuously in high-demand inkjet printing tasks.

How to Get in Touch with TOPSFLO for Expert Assistance?

Maintaining a consistently stable flow and using ink fluids with the appropriate viscosity are crucial for overall printing quality. Any abnormalities in the ink supply system can lead to poor printing quality, error messages, and even costly product recalls. Therefore, choosing the right ink pump for your continuous inkjet printer is of utmost importance.

TOPSFLO specializes in the development and production of various micro pumps for printers. They have extensive experience and pump solutions, and they offer customized services to meet different customer needs. Please contact their sales engineers for printer pump application cases and pump information! Email: [email protected] or [email protected]

youtube

0 notes